There are three standard sizes for the basic Frigid-X™ vortex tubes – the mini size which uses 2, 4 or 8 SCFM, the most common (medium) size which uses 10, 15, 25, 30 and 40 SCFM, and the large sizes which use 50, 75, 100 and 150 SCFM. The large sizes are used in heavy industry but can cool to over 10,000 BTU/hr. Vortex tubes normally come with the “hot end” adjustable to control the flow and temperature out the cold end. The more flow out the hot side, the lower the temperature out the cold side. It is careful to note that the cooling effect (BTU/hr.) is determined by both flow and temperature drop. So if cooling effect is important, then the flow out the cold end should be between 60% – 80%. If the cold temperature is most important, then the flow out the cold end should be under 50%. All vortex tubes have a “generator” which is sized for a certain flow. There are basically two kinds of generators- one for cooling effect and then a second kind which limits the flow out the cold end, to achieve very low temperatures. Depending on the temperature and pressure of the incoming compressed air, it is possible to achieve cold end temperatures as low as minus 40 and even minus 50 degrees F.

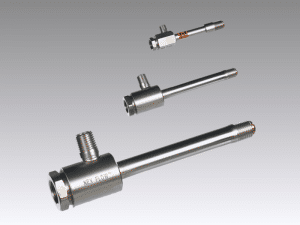

Our Stainless Steel vortex tube comes assembled with a brass generator as a standard item rather than cheap plastic for longer lifespan and for applications in high-temperature environments. With virtually no moving parts, the vortex tube takes compressed air and converts it to cold air as low as minus 50° F (minus 46° C) at one end and hot air at the other up to 260° F (127° C).