Vortex Tube Tool Cooling Systems

- Pneumatic Products

- Nex Flow-Air Products

- Vortex Tube and Industrial Spot Cooling

- Vortex Tube Tool Cooling Systems

Download PDF (2.126,5 Kb)

Download PDF (2.126,5 Kb)

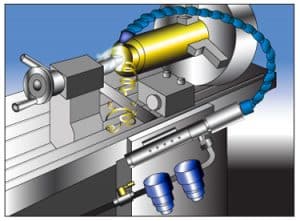

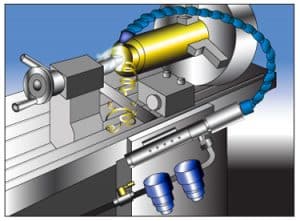

The Frigid-X™ Tool Cooling System for dry machining applications –

replaces polluting and often toxic mist systems to improve dry machining

operations. No mess, no residue and low in cost.

It is efficient and can improve dry machining operations and assist

in spot cooling applications for a variety of industrial machining

processes but increasing machining rates and extending tool life.

Produces cold air at approximately 50º F (28º C) below supply air

temperature. The unit is muffled for quiet operation. No moving parts

assure long life, maintenance-free operation while extending tool life

and improving production rates.

Can often replace costly mist coolants and certainly improves the

quality and output of all types of dry machining operations from metals

to plastics. Unit is low cost, no electricity with no moving parts and

is essentially maintenance free.

APPLICATIONS

- Sharpening Tools

- Routing

- Machining Plastics

- Drill And Cutter Grinding

- Milling, Drilling, Routing And Surface Grinding

- Plunge And Form Grinding

- Setting Hot Melt Adhesives

- Laser Cutting

- Tire And Rubber Grinding

- Band Saw Blade Cooling

- Chill Roll Nip Cooling

ADVANTAGES

- No Moving Parts

- Quiet

- Driven By Air, NOT Electricity

- Small And Lightweight, Portable

- Milling, Drilling, Routing And Surface Grinding

- Low In Cost

- Superior Design And Performance

- Maintenance Free Operation

- Made Of Durable Stainless Steel And Metal Arts – NO Cheap Plastic Parts

- Improves Production Rates And Finished Part Remains Dry

- Prevents Burning

- ImprovesTolerance Control

- Eliminates Coolant Costs

- System Uses Strong Magnetic Base